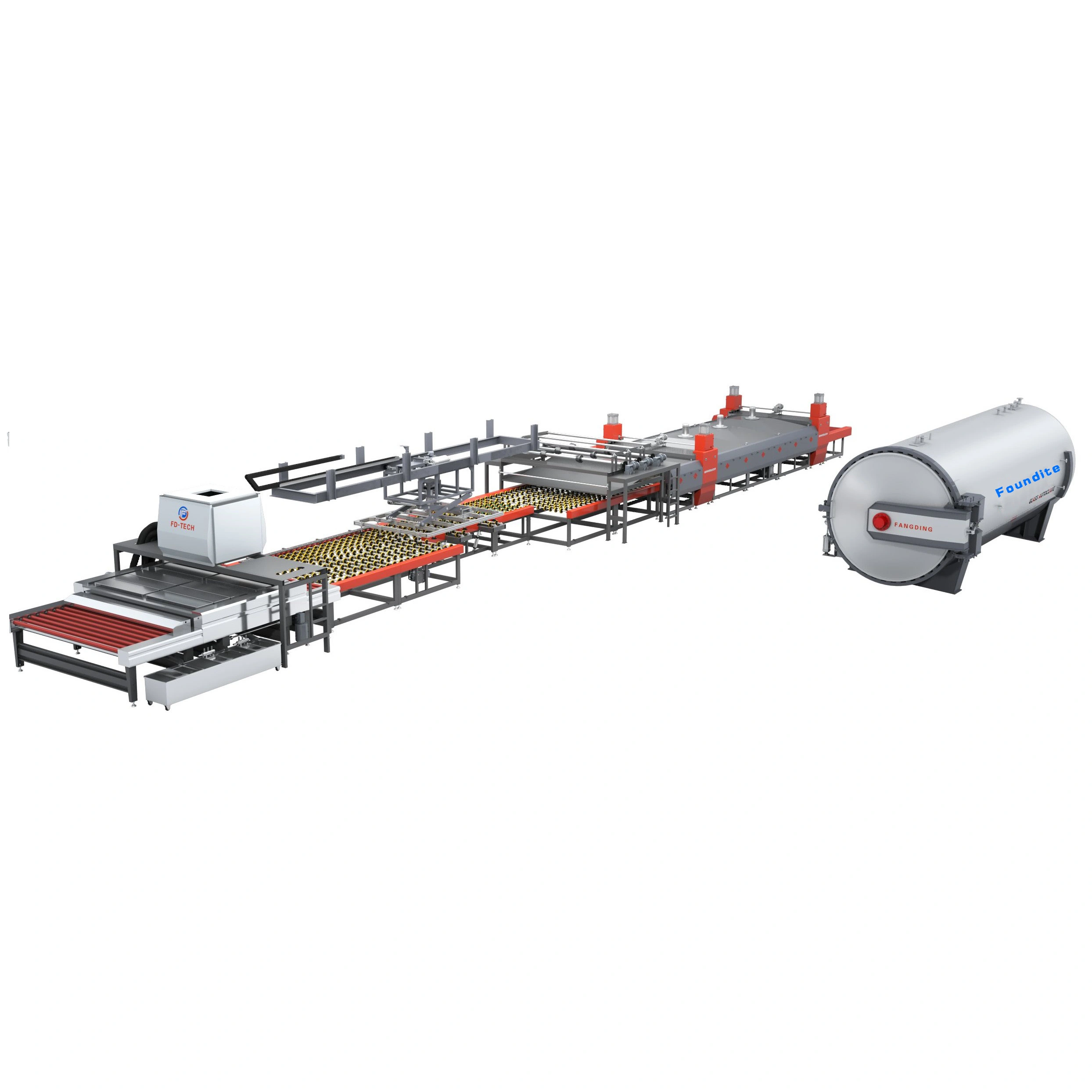

Pvb/sgp/tpu/eva Laminated Glass Production Line With Glass Autoclave

Advantages of the whole line

● The whole line adopts PLC centralized control system, variable frequency speed regulation, and has three HMI interface operations.

● The whole line design fully considers special controls such as high efficiency, energy saving, environmental protection, and noise reduction.

● The film roller machine is equipped with automatic film unwinding and winding functions. The three film rollers are placed horizontally for easy operation.

● The initial pressure section has a reasonable structure and is easy to operate. The whole machine runs smoothly and is controlled by the central PLC system. The heating area is evenly distributed and equipped with medium-wave infrared heating tubes for heating. The temperature is measured and controlled in this area, and the maximum temperature is 250ºC (adjustable).

● The glass autoclave is automatically controlled by PLC and operated through the human-machine interface to achieve safety, reliability and efficiency.

| Item | Value |

| Product name | PVB glass laminating line |

| Application | Automotive Glass &Construction Glass Lamination |

| Max glass size | 2500*6000mm |

| Min glass size | 400*400mm |

| Control system | PLC Auto |

| Total Power Supply | 457KW(170+232+55kw) |

| Total Weight | 45000KG |

| Total floor space | 45*8m |

| Production capacity | 500 sq.m per cycle |

| Processing cycle | 4.5-5hrs |

Intelligent glass cleaning and drying machine

The machine has 3 pairs of brush rollers, 2 pairs of which are hard brush rollers for ordinary glass cleaning, and 1 pair of soft brush rollers for Low-E glass cleaning. It is equipped with a detection device. When Low-E glass is detected, the hard brush roller will automatically lift up.

◎ Maximum glass width: 2500 mm

◎ Minimum glass specification: 400×400 mm

◎ Glass thickness: 3~19 mm

◎Speed range: 12 m/min

Automatic bidirectional positioning conveyor

Designed for fast, rhythmic operation of cleaning, transmission and positioning.

◎ Maximum glass specification: 2500 * 4000 mm

◎ Positioning accuracy: ±0.3 mm

◎Transmission speed: 15 - 20 m/min

High-precision automatic adsorption hanger

The high-precision suction cups are reasonably distributed, the suction cup position combination is durable, and the suction cups do not need to be moved during the production process.

◎ Maximum bearing weight: 900 kg

◎ Air source: pressure 0.6 MPa, flow rate 8.3 L/min

◎ Maximum vacuum pressure of suction cups: -0.08 MPa

◎ Number of suction cups: 24

◎ Assembly accuracy: ±0.3 mm~0.5 mm

Three rollers PVB film rack

◎ Quantity of loading film :3 rolls

Forced convection infrared roller pre-pressing machine Features of infrared roller press:

A synthetic glass thickness measurement and gap automatic adjustment device is installed before the preheating section.

Both the heating section and the preheating section are equipped with medium-wave infrared heating elements to effectively heat the intermediate PVB.

The upper and lower boxes of the heating section and the preheating section are separated for easy maintenance.

◎ Maximum glass width: 2500mm

◎ Minimum glass size: 400*600mm

◎ Processing glass thickness: 6 - 80mma

◎ Transmission speed: 0.5~3.0m/min

Forced convection autoclave for PVB film

◎Processed Glass Size. Max Size:2500mm*6000mm(small quantity);

2440mm*6000mm(mass production)

◎ Sheet glass thickness:3~19mm

◎ Total Power:290KW(air compressor unit and water pump included)

(autocalve:232KW,air compressor unit:55KW,water pump:3KW)

◎ Water supply:0.7m³/min,pressure: 3~6kg/㎠

◎ Cooling tower capacity:≧30㎥

◎ Air source:1.3Mpa,rate of flow :≧7.5m³/min

◎ Floor Space:9600mmX3500mm(L*W).

◎ Weight:≧21T

Laminated glass production line is selective

Customers can choose fully automatic laminated glass production line or intelligent laminated glass production line according to factors such as site and order. At the same time, our sales manager will also provide appropriate suggestions based on the actual situation and needs of the customer, and customize a dedicated laminated glass production line to better serve the customer.

Packaging and delivery

During the shipping process, we will package and cover the equipment appropriately to avoid any unexpected situations and ensure that the equipment arrives at the customer's factory in good condition. Attach warning signs and provide a detailed packing list.

Our services

Pre-sales service: Will provide suitable equipment models and relevant equipment technical information according to customer needs, and provide basic design plans, general drawings and layout drawings when quoting.

Sales service: After the contract is signed, Will strictly implement the relevant standards of each project and each production process, communicate with customers in a timely manner about the progress of the equipment, and ensure that customer requirements are met in terms of process, quality and technology.

After-sales service: Will send experienced technicians to the customer's site for equipment installation and training. At the same time, within the one-year warranty period, our company will provide corresponding equipment maintenance and repair.

In terms of service, you can fully trust us. Our after-sales staff will promptly feedback any problems encountered to the technicians, and the technicians will also give corresponding guidance.

Our honor certificate

Exhibition

The company participates in world-renowned glass industry exhibitions every year. During the exhibitions, we demonstrate our high-end functional masterbatches, EVA interlayers and TPU interlayers, as well as our professional laminated glass equipment to customers through on-site processing of laminated glass, and have received unanimous praise from customers!