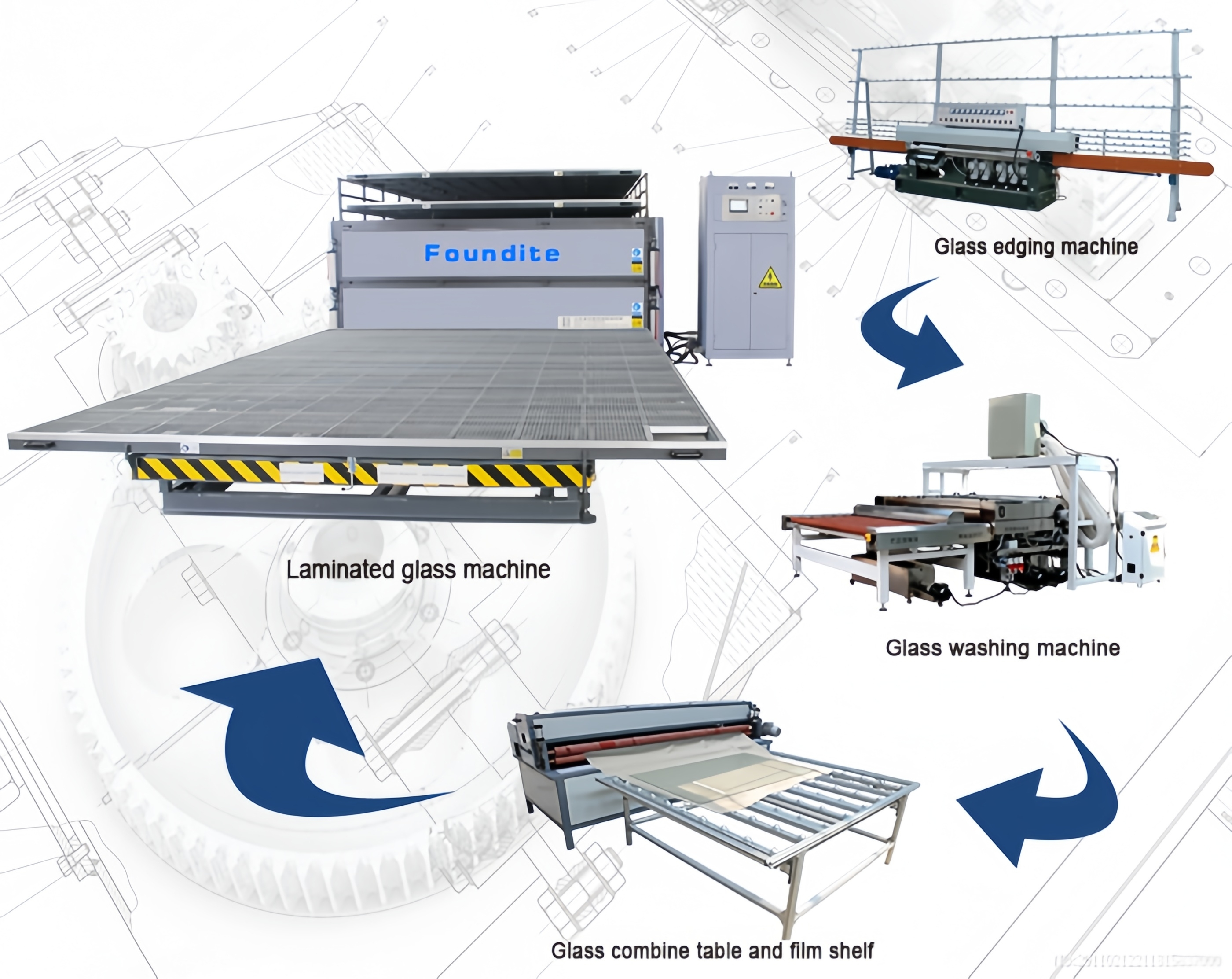

Tempered intelligent EVA laminated glass processing furnace for decorative glass

Product advantages

1). PLC control system:

The glass production process is computer controlled, and the heating time and temperature can be adjusted according to the thickness of the glass. It is easy to operate and reduces errors.

Equipped with lightning protection and voltage stabilization devices, it can support 220V - 440V three-phase power supply.

2). Heating system:

Adopt 304 stainless steel heating unit and carpet heating. Rapid heating, uniform heating, and improved yield rate.

The heating wire is external and easy to maintain.

It uses imported silicone bags, which have good sealing, anti-aging, and tear resistance, can withstand high temperatures of 180 degrees Celsius, and the cumulative thickness of glass fiber reaches 36 mm.

Product Advantages

The vacuum pump designed in Germany can work continuously for 24 hours. The vacuum degree of this machine can reach -0.09-0.098MPa.

The vacuum pump is equipped with a vacuum buffer tank to ensure that there will be no product waste in the event of a sudden power outage, and the vacuum can be maintained for 12 hours.

4). Insulation system:

The body frame adopts an energy-saving design and uses bearing steel, which has strong bearing capacity and small footprint.

This machine uses a 10 cm thick customized composite material to effectively prevent hot air from escaping from the inside of the machine, improving the mechanical strength and thermal insulation performance of the machine.

Material introduction

This tempered intelligent EVA laminated glass processing furnace for decorative glass is crafted using high-quality materials to ensure durability and efficiency. The furnace is designed specifically for three layers of laminated glass, making it suitable for various decorative glass applications. With precise construction and reliable materials, this product offers a superior processing solution for producing high-quality laminated glass efficiently.

◎ High-quality

◎ Durable

◎ Innovative

Product Introduction

Our company was founded in 2003, with a factory of 20,000 square meters and more than 100 people. Our products are 2-layer glass laminator, 3-layer glass laminator, 4-layer glass laminator and EVA film. We have exported to more than 68 countries and regions, and most of them are imported to Europe.

Our equipment is self-developed. We have more than 14 years of rich experience in loading and delivery of glass laminators.

Our honor certificate

FAQ

Our honor certificate