a ) The environmental requirements of the packaging area are as follows:

1 ) The temperature is generally 15C-30C;

2 ) Relative humidity is generally 20%-50%;

3 ) Cleanliness is generally 10000 and above.

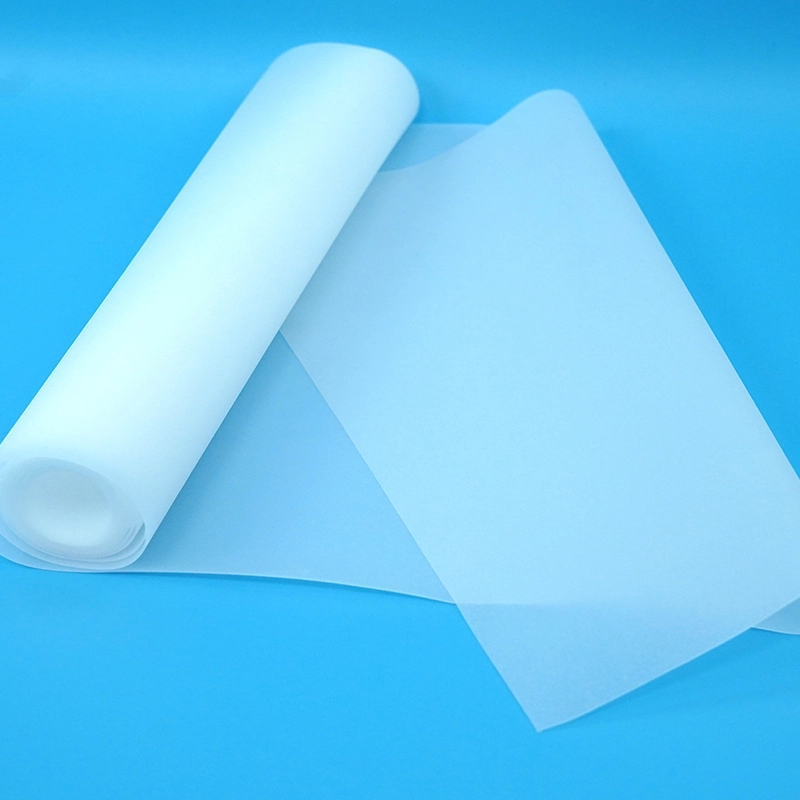

b ) Adopt protective packaging to ensure that EVA film does not cause mechanical and physical.

c ) Packing list includes product name , quantity and related documents.

d ) The packing case is shockproof , sand and dust proof and rain proof .

e ) The packing box marks shall meet the requirements of GB / T 191,including "fragile articles", "afraid of sun", "afraid of radiation","afraid of rain", "no tumbling", "limit of stacking quality", "limit of stacking layers",etc.